Home »

IPS E.Max Press

![]()

* Flexural strength 160 MPa

* Ideal for: veneer facing and Inlay

The IPS Empress all-ceramic material for use in the dental laboratory is made of an extremely homogeneous leucitebased ceramic, which scatters light like natural enamel andblends in well with its surroundings. This material exhibits lifelike translucency and convincing esthetic properties.

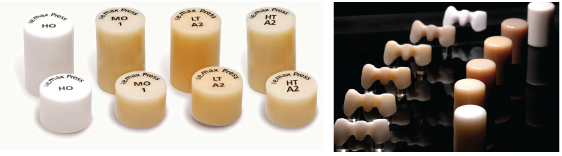

- HT ingots (High Translucency)

The HT ingots are available in 16 A-D and 4 Bleach BL shades. Given their high translucency, they are ideal for the fabrication of smaller restorations (e.g. inlays and onlays). They can efficiently be individualized using the staining technique.

LT ingots (Low Translucency)

The LT ingots are available in 16 A-D and 4 Bleach BL shades. Given their low translucency, they are ideal for the fabrication of larger restorations (e.g. posterior crowns). They impress users with their lifelike brightness value and chroma. The appearance is further maximized by means of the cut-back technique.

MO ingots (Medium Opacity)

The MO ingots are available in 5 group shades (MO 0-MO 4). Given their opacity, they are ideally suitable for the fabrication of frameworks on vital, slightly discoloured preparations. They provide an excellent basis for lifelike restorations fabricated with the help of the layering technique.

HO ingots (High Opacity)

The ingots are available in 3 group shades (HO 0-HO 2). Given their high opacity, they are ideally suitable for the fabrication of frameworks on severely discoloured preparations or titanium abutments. They mask the dark subsurface and enable highly esthetic results.

Impulse ingots (Value, Opal)

The new Impulse ingots are available in 3 Value (Value 1, 2, 3) and 2 Opal shades (Opal 1, 2). They are mainly used for the fabrication of thin veneers, veneers, table tops, partial and single crowns.

Depending on the favoured processing technique (staining, cut-back or layering technique) and the respective patient situation, a suitable ingot can be found. Individual characterization or veneering is carried out using the coordinated stains and layering materials of the IPS e.max Ceram veneering ceramic. For processing of IPS e.max Press in the EP3000 and EP5000 press furnaces, the two investment materials IPS PressVEST and IPS PressVEST Speed are available.

Advantages

- High strength (400 MPa) and high esthetics

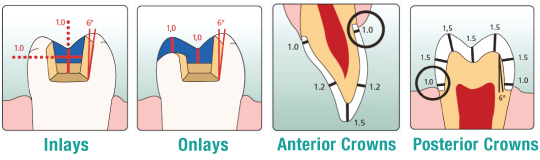

- Minimally invasive, accurately fitting restorations

- Four levels of translucency and additional Impulse ingots for maximum flexibility

- Lifelike esthetics, irrespective of the shade of the preparation

- Adhesive, self-adhesive or conventional cementation depending on the indication